In today’s fast-paced industrial landscape, unplanned equipment downtime can be a major setback, leading to lost productivity and increased costs. This is where Predictive Maintenance (PdM) comes into play a proactive approach that leverages data and advanced diagnostics to predict and prevent equipment failures before they occur.

At UTE, we go beyond traditional maintenance methods by integrating advanced technology and expert service to keep your machinery running at peak performance.

Why Early Diagnosis Matters:

Small issues can quickly turn into costly failures:

- A clogged filter doesn’t just reduce efficiency: it can lead to engine overheating.

- A worn belt doesn’t just slip: it can damage critical components of the Engines

Unplanned repairs mean downtime, missed deadlines, and frustrated clients. But with predictive maintenance, you get real-time alerts that help you act before minor problems become major headaches.

How UTE Delivers Predictive Maintenance

- Advanced Diagnostics with CAT® Electronic Technician (CAT ET).

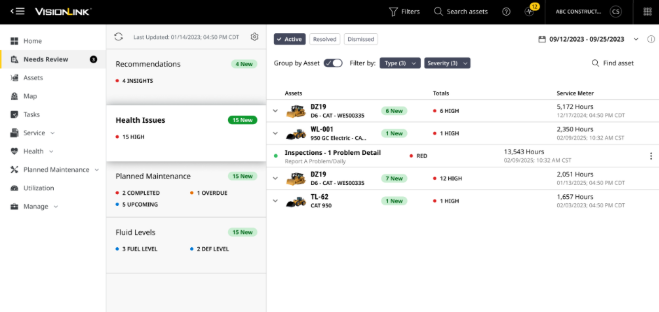

Our team uses CAT ET, a powerful diagnostic tool that monitors engine performance, hydraulic systems, and more flagging potential issues before they cause failures. - Cat® VisionLink® for Smart Fleet Management.

VisionLink® delivers actionable insights to help take the guesswork out of fleet, productivity and safety management. By offering easy to understand and actionable insights customers can ensure they have the right assets in the right place at the right time, ready to work. As an example with these predictive alerts, you’ll know exactly when a filter needs changing or coolant levels are low, so you can act fast. - Certified & Skilled Technicians.

UTE’s service team consists of Cat® certified technicians who are trained to handle complex diagnostics and repairs, ensuring your equipment receives the best care possible. - Cat® VisionLink® for Smart Fleet Management.

VisionLink® delivers actionable insights to help take the guesswork out of fleet, productivity and safety management. By offering easy to understand and actionable insights customers can ensure they have the right assets in the right place at the right time, ready to work. As an example with these predictive alerts, you’ll know exactly when a filter needs changing or coolant levels are low, so you can act fast. - Island wide Coverage.

No matter where your operations are located, UTE’s Island wide service network ensures prompt support whenever you need it. - Cat® Service Clinics for Knowledge Sharing.

We regularly conduct Cat® Service Clinics to provide services and educate customers on best maintenance practices. This year, we held clinics in Jaffna and Elahera, offering discounted services and insights. - Remote Monitoring for Proactive Maintenance.

With remote monitoring systems, UTE monitor equipment performance in real-time, allowing us to schedule maintenance only when necessary, maximizing uptime and efficiency.